Cement, a cornerstone of modern construction, plays a crucial role in shaping our urban environments and meeting the demands of a growing global population. However, its widespread use comes with a significant environmental cost. According to the World Economic Forum, cement production is responsible for approximately 8% of global CO2 emissions, largely due to the energy-intensive processes involved and the decarbonation of limestone during clinker production.

While the environmental challenges of cement, such as greenhouse gas emissions, resource consumption, and impacts on biodiversity, are undeniable, the need for durable and scalable construction materials remains essential. With populations increasing and urbanization accelerating, finding innovative solutions to reduce the carbon footprint of cement is more important than ever. Transitioning to greener materials and adopting sustainable practices in cement production are not just environmental imperatives. They are also vital for supporting the infrastructure demands of a growing world in a way that balances development and ecological preservation.

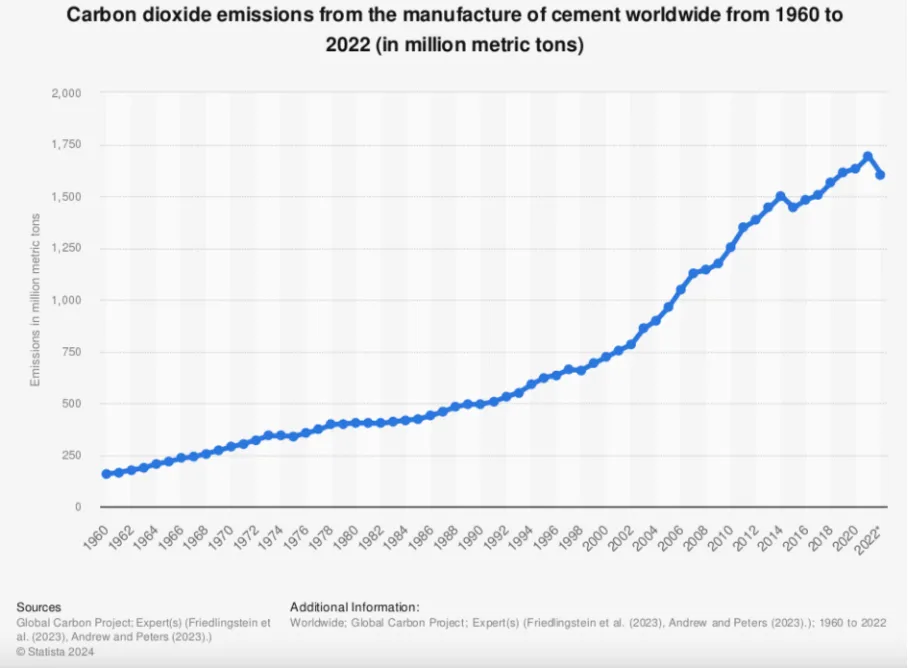

As this graph shows, CO2 emissions from cement production have more than doubled since 2000:

Faced with these challenges, the construction sector is actively exploring more sustainable alternatives to traditional cement. Here are some promising innovations:

• Low or zero clinker cements: These cements replace part of the clinker with other materials such as fly ash, blast furnace slag or silica ash, thereby reducing the CO2 emissions associated with their production. The French company Hoffmann Green Cement Technologies is a pioneer in the manufacture of cement without clinker.

• Hemp concrete: Using industrial hemp as an aggregate, this concrete is not only lightweight and insulating, it also sequesters carbon, helping to reduce global greenhouse gas emissions. The British company Hempcrete uses hemp and lime, as well as other bio-sourced materials, to create ecological and sustainable construction solutions.

• Geopolymer concrete: Made from geopolymeric materials that do not require clinker, this type of concrete can reduce CO2 emissions by up to 80% compared with traditional Portland cement concrete. The American company Geopolymer Solutions specializes in this material.

• Concrete recycling: Although this method does not directly replace cement, it does reduce the demand for new construction materials by reusing existing concrete, which indirectly reduces emissions linked to the production of cement.

• Magnesium oxychloride cement: Known as ‘Sorel cement’, this material is made from magnesium, an element that is more abundant and less polluting than the calcium used in Portland cement. The French company TIMAB Magnesium is an innovative player in this field.

These alternative materials are being promoted not only for their potential to reduce carbon emissions, but also for their mechanical properties, which are often comparable or even superior to those of traditional concrete. Nevertheless, their adoption remains hampered by often higher initial costs, a lack of regulatory standards and a certain resistance to change in the construction industry.

Switching to greener building materials is crucial to achieving global climate goals. As the world strives to limit global warming to 1.5°C in line with the Paris Agreement, innovation in the composition of building materials will play a key role. The transition to alternatives to cement is not only an environmental necessity, but also an economic opportunity for the construction sector for a number of reasons.

Firstly, although some alternative materials can be more expensive in the short term, they can offer greater durability and strength, reducing maintenance and replacement costs in the long term. For example, some alternative cements such as geopolymer cements can offer better resistance to corrosion and sulphates, making them more suitable for infrastructure exposed to harsh environments. Secondly, some European countries such as France, the Netherlands and Spain offer subsidies or tax credits linked to the use of environmentally-friendly materials. Finally, alternatives to cement can attract investors and new customers who favor sustainability, which means opportunities for growth.

Daniel has 20 years of experience in business and financial journalism, having worked in Zurich, Tokyo, Buenos Aires, and Mumbai. Over the years, he has covered start-ups, cleantech, and the Swiss construction sector in depth.

Deeply concerned about environmental issues and fully aligned with Raphaël’s vision of making the ecological transition more accessible and impactful for companies, he joined the project and co-found GoEko alongside him.